-

Product DescriptionCompany Info.<>

- Principle:

- Vacuum filtration

- Style:

- Vertical type

- Applicable object:

- Transformer oil

- Model:

- ZJA-J30

- Filter type:

- Fibre

- Performance:

- High efficiency filtration

- Rated flow:

- 1.8 m3/h

- Working pressure:

- 0.4 MPa

- Operating noise:

- 60-80 dB

- Inlet and outlet pipe diameter:

- 25 mm

- Deemulsification number:

- 10 min

- Cleanliness:

- 6 NAS

- Overall dimension:

- 00 mm

- Effective filtration area:

- 00 ㎡

- Machine power:

- 34 kw

ZJA series transformer insulation oil double stage vacuum oil filter is suitable for power plant, power station, electric power company, substation industry, metallurgy, petrochemical, machinery, transportation, railway and other industries.

It is applied to the purification of insulating oil of transmission and transformation equipment above 110/220/500KV to remove moisture, gas and mechanical impurities, so as to improve the withstand voltage strength and oil quality of insulating oil and ensure the safe operation of high-voltage electrical equipment. After treatment, the oil reaches the national standard, which is a common oil filter equipment in the electric power industry. It can also be used for vacuum oiling and drying of transformers. Live working on site.

Applicable oil:new imported oil, transformer oil, ultra-high voltage transformer oil, capacitor oil, switch oil, reactor oil, refrigeration oil, aerospace hydraulic oil and other high-demand precious oil

Main function:improve transformer oil insulation grade, remove moisture, impurities, acetylene gas in oil, improve oil cleanliness.

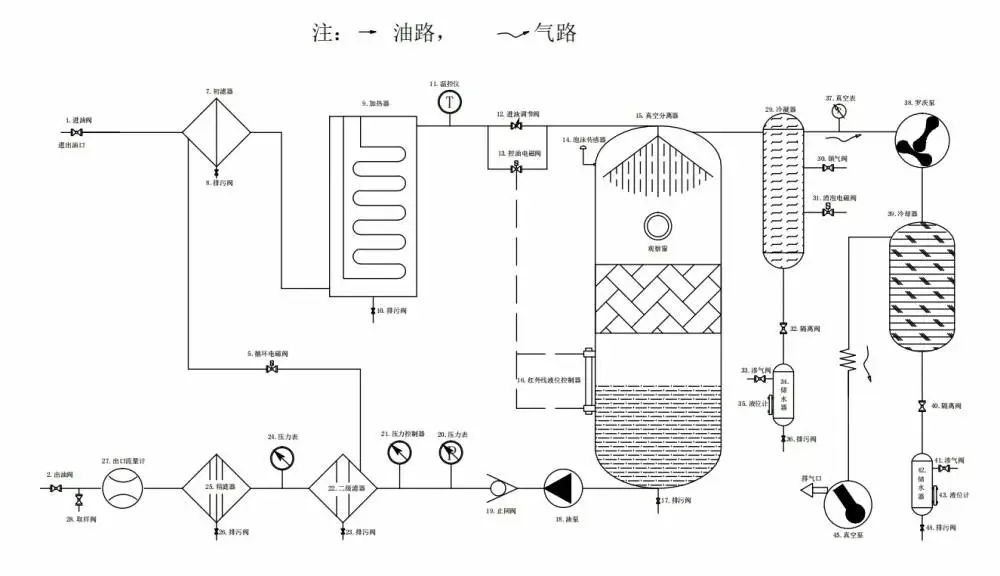

1) two-stage vacuum pumping speed and advanced dehydration, degassing system, using large-area three-dimensional flash technology, can quickly and efficiently remove water, impurities, hydrocarbons and other harmful components in the oil, improve the flash point and dielectric strength of insulating oil.

2) It can meet the requirements of vacuum pumping and vacuum oiling of transformer body on installation or maintenance site.3) Precision filtration system, high-quality filter element, multi-stage filtration step by step encryption, can effectively remove mechanical impurities in the oil, and configure filter element pollution detection reminder function.

4) Advanced automatic constant temperature control system, automatic liquid level control system, automatic defoaming control system, automatic pressure protection system and excellent configuration to ensure high performance operation of equipment.

5) Online oil filtration, unattended, operation status displayed by indicator light.

6) The machine user-friendly design, low noise, simple operation, long maintenance interval, low energy consumption to save operating costs.

7) The whole machine is equipped with interlocking safety protection, oil discharge system, vacuum system and heating system interlocking to avoid adverse effects caused by misoperation.

8) Set filter replacement index, filter saturation shutdown device.

9) equipped with leakage, overload shutdown device to protect the motor.10) With phase sequence, phase loss protection function, sudden shutdown safety control.

Main technical parameters:

The appearance size and weight of the equipment are for reference only. With the continuous development of the product, the actual product shall prevail.

technical parameter table

indicator name

unit

ZJA-J30

ZJA-J50

ZJA-J75

ZJA-J100

ZJA-J150

ZJA-J200

ZJA-J300

flow

L/H

1800

3000

4500

6000

9000

12000

18000

vacuum degree

Pa

≤133

ultimate vacuum

Pa

≤7

work stress

Mpa

≤0.5

operating temperature

℃

30 ~ 80

working power supply

380V/50Hz (upon customer request)

working noise

dB(A)

≤78

heating power

kW

30

36

54

72

108

120

144

total power

kW

34

40

60

78

118.5

132

158

inlet and outlet pipe diameter

mm

25

32

42

42

50

50

60

Oil parameters after cyclic treatment

breakdown voltage

kV

75 (ball)

water content in oil

ppm

3 ~ 5 (GB7600) Traces (GB/T260)

gas content

%

≤0.1 (volume ratio)

impurity

µm

1~5 Free carbon (GB/T511)

Appearance size (mm)

long

1450

1600

1800

1900

2200

2200

2300

wide

1000

1100

1250

1250

1500

1550

1800

tall

1800

1800

1900

2100

2200

2300

2500

Technical performance:

1)Vacuum system: two-stage high-speed vacuum system, multi-stage vacuum resolution separation system, advanced dehydration and degassing system, using large-area three-dimensional flash technology to quickly and efficiently remove harmful components such as moisture and gas from oil. The cleanliness, dryness, breakdown voltage and one-time filtering effect of oil are greatly improved, and the oil treatment period is shortened.

2)Filtration system: precision multi-stage filtration system, filtration accuracy step by step encryption, can effectively remove mechanical impurities in the oil; high-quality filter material, corrosion resistance, good mechanical strength and durability, but also can be repeatedly cleaned and used.3)Heating system: new efficient electric heating system, low heating load, uniform heating, low energy consumption.

4)Intelligent control system: sensitive pressure protection device and infrared liquid level control system, oil inlet and heating linkage system, constitute the whole machine chain safety protection system, photoelectric foam sensor, automatic defoaming function, eliminate oil injection, oil leakage phenomenon, simple operation, safe and reliable.

Optional devices:

A Optional PLC(intelligent programmable logic control system): touch screen man-machine dialogue operation interface, and dynamic display.B imported parts (such as: imported brand vacuum pump set, motor oil pump set, filter elements, electrical components, instruments, etc.).

C Flowmeter.

D configuration frequency conversion system can realize the flow selection when filtering oil or filling oil.E online micro water tester.

F Vacuum gauge.

G Insulation oil withstand voltage tester

Optional shape structure:

Base structure:1. Mobile roller type 2. Fixed installation type 3. Mobile trailer type

Structure: A, open B, canopy C, fully enclosed rain shelter D, canvas shelter

Material selection: 1, high carbon steel 2, oil stainless steel 3, all stainless steel

Material selection: 1, high carbon steel 2, oil stainless steel 3, all stainless steelColor options: milk white, sky blue, grass green, industrial gray, warning yellow and so on

Related accessories:Free delivery of a set of accessories (including hoop, glass tube, oil resistant rubber pad, PVC steel wire reinforced hose in and out of each 5 meters)

Freight description:manufacturers responsible for national freight, door-to-door delivery.

Supply cycle:standard products, stock generally 2-3 working days can be shipped; customized products, 10-20 working days production and delivery.

Packing:bamboo wooden case packing, in line with the general domestic and foreign transportation requirements.

Quality assurance: The warranty period of the product is 12 months after startup;

Technical service:all (non-artificial) equipment problems within the warranty period are repaired free of charge by the manufacturer, and all non-artificial damaged parts are free of charge (except consumables).- Name(chinese)

- Name(English)

- Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Chongqing, China

- Nearby port

- Dalian,Qinhuangdao,Qingdao,Yantai,Lianyungang,Shanghai,Fuzhou,Shantou,Shenzhen,Guangzhou,Zhuhai

Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd. is a manufacturer of oil filtration and purification equipment. It independently develops, designs, produces and sells it, and can accept processing of incoming samples and customization on demand. Please consult directly for type selection and technical issues: 173--2397--4465 (Feng Jun). Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd. focuses on producing a series of products including: lubricating oil hydraulic oil vacuum filters, transformer oil dual-stage vacuum filters, steam turbine oil vacuum filters, portable filtration refuelling machines, waste oil regeneration filters, gasoline and diesel coalescence separation filters, pressure type plate and frame oil filters, etc., which can meet the filtering needs of different industries for various types of lubricating oils. And provide targeted solutions based on the special needs of different customers. It provides a strong guarantee for customers 'safe production and cost reduction. Since its establishment, Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd. has been continuously pioneering and innovating, extensively drawing on advanced oil filtration and purification technologies at home and abroad, and relying on strong industry technology, modern corporate management, products with stable performance and fast and perfect after-sales service, it has developed into a domestic large-scale oil filter production base with excellent quality, many varieties and strong strength. Our products are widely used in many industries such as power, petroleum, chemicals, metallurgy, mining, machinery, aviation, shipbuilding, railway, pharmaceuticals, food oil processing, etc. There are also a variety of special configuration styles for you to choose from: enclosed oil filter, explosion-proof oil filter, trailer oil filter truck, PLC fully automatic oil filter, touch screen controlled oil filter, fully imported configuration filtration and purification machines, etc. According to the special needs of different customers, we can provide targeted solutions, providing a strong guarantee for customers 'safe production, energy conservation, and reduction of production costs. Tongrui people adhere to the corporate spirit of "quality-oriented, abiding by credit, striving for excellence, pioneering, truth-seeking and innovative". From beginning to end, Tongrui people rely on technology, market-oriented, customer-centered, boldly innovate, and devote themselves to improving the level, taking improving the quality of oil products and protecting the ecological environment as their responsibility, and making every effort to create the "Tongrui" brand. The company is willing to work with colleagues from all walks of life to work together, and make unremitting efforts to create a national industry in the positive spirit of cooperation of treating each other with sincerity and win-win cooperation. Registered address: 27-01, Building 17, No. 198, Shuangcheng Road, Dadukou District, Chongqing City Tax word: 91500104798036968C Opening bank: Bank of China, Chongqing City Dadukou Branch Account number: 110 209 123 081- Name(chinese)

- Name(English)

- Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd.

- China credit code

- Identity Verification

- Address

-

Chongqing, China

- Nearby port

- Dalian,Qinhuangdao,Qingdao,Yantai,Lianyungang,Shanghai,Fuzhou,Shantou,Shenzhen,Guangzhou,Zhuhai

Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd. is a manufacturer of oil filtration and purification equipment. It independently develops, designs, produces and sells it, and can accept processing of incoming samples and customization on demand. Please consult directly for type selection and technical issues: 173--2397--4465 (Feng Jun). Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd. focuses on producing a series of products including: lubricating oil hydraulic oil vacuum filters, transformer oil dual-stage vacuum filters, steam turbine oil vacuum filters, portable filtration refuelling machines, waste oil regeneration filters, gasoline and diesel coalescence separation filters, pressure type plate and frame oil filters, etc., which can meet the filtering needs of different industries for various types of lubricating oils. And provide targeted solutions based on the special needs of different customers. It provides a strong guarantee for customers 'safe production and cost reduction. Since its establishment, Chongqing Tongrui Filtration Equipment Manufacturing Co., Ltd. has been continuously pioneering and innovating, extensively drawing on advanced oil filtration and purification technologies at home and abroad, and relying on strong industry technology, modern corporate management, products with stable performance and fast and perfect after-sales service, it has developed into a domestic large-scale oil filter production base with excellent quality, many varieties and strong strength. Our products are widely used in many industries such as power, petroleum, chemicals, metallurgy, mining, machinery, aviation, shipbuilding, railway, pharmaceuticals, food oil processing, etc. There are also a variety of special configuration styles for you to choose from: enclosed oil filter, explosion-proof oil filter, trailer oil filter truck, PLC fully automatic oil filter, touch screen controlled oil filter, fully imported configuration filtration and purification machines, etc. According to the special needs of different customers, we can provide targeted solutions, providing a strong guarantee for customers 'safe production, energy conservation, and reduction of production costs. Tongrui people adhere to the corporate spirit of "quality-oriented, abiding by credit, striving for excellence, pioneering, truth-seeking and innovative". From beginning to end, Tongrui people rely on technology, market-oriented, customer-centered, boldly innovate, and devote themselves to improving the level, taking improving the quality of oil products and protecting the ecological environment as their responsibility, and making every effort to create the "Tongrui" brand. The company is willing to work with colleagues from all walks of life to work together, and make unremitting efforts to create a national industry in the positive spirit of cooperation of treating each other with sincerity and win-win cooperation. Registered address: 27-01, Building 17, No. 198, Shuangcheng Road, Dadukou District, Chongqing City Tax word: 91500104798036968C Opening bank: Bank of China, Chongqing City Dadukou Branch Account number: 110 209 123 081 -

Send your message to this supplier*From:*To:

Ms. FENG

*Message:

Ms. FENG

*Message:Inquiry

Copyright © 2003 - 2026 Goepe.com All rights reserved.